Ribbing in the context of car repair can have various meanings, ranging from the surface structure of certain car parts to colloquial terms for damage or ripping off. In this article, we will explore the different aspects of “ribbing” and provide valuable information for your work as a car mechanic.

What Does “Ribbing” Mean in Car Repair?

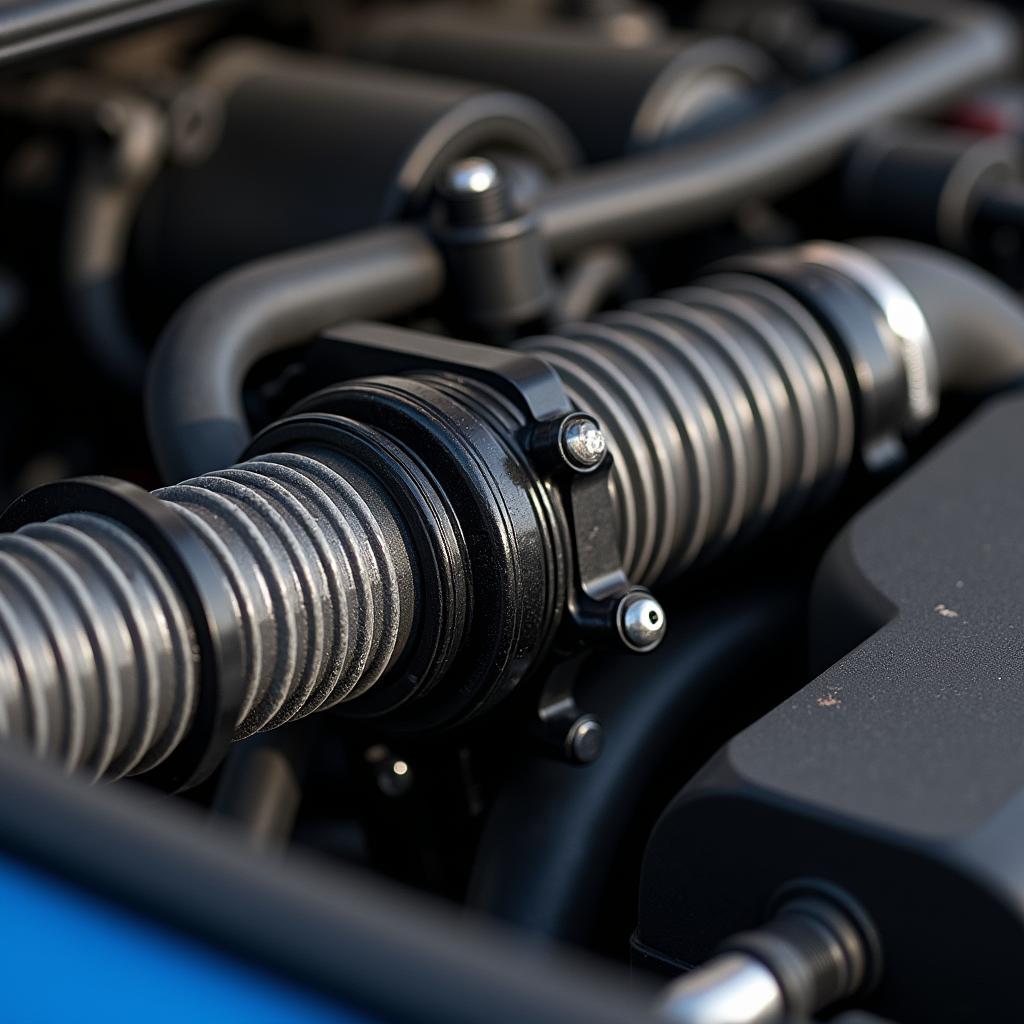

The term “ribbing” can refer to several aspects. Firstly, it often describes the surface structure of components such as hoses, belts, or radiators. These ribs are designed to increase the surface area, thereby improving heat dissipation or grip. Secondly, “ribbing” is also used colloquially for inflated prices or unfair billing in repair shops. “Ripping someone off” or “scamming” are similar expressions. Thirdly, “ribbing” can also describe damage to a component, for instance, a torn or broken rib on a hose.

Ribbing on a radiator hose

Ribbing on a radiator hose

Ribbing as a Structural Element

In a technical sense, ribbing is an important design feature. It increases the surface area of a component, thereby improving its function. On radiator hoses, for instance, the ribbing allows for more efficient heat dissipation, contributing to optimal engine cooling. On V-belts, the ribbing ensures better power transmission and prevents slipping. Professor Dr. Hans Müller, author of “Innovative Cooling Systems in Automotive Engineering,” emphasizes the importance of ribbing for the efficiency of modern engines.

Ribbing and Cost Traps

Unfortunately, the term “ribbing” is also used in a negative context. Some repair shops exploit their customers’ lack of knowledge and charge inflated prices for repairs or replace functional parts. To protect yourself from such “ribbing,” you should inform yourself about average costs beforehand and obtain multiple quotes. “Trust is good, control is better,” says experienced mechanic Karl Schmidt.

How to Identify Damage on Ribbed Components

Cracks or breaks in the ribs of hoses or belts can lead to malfunctions. In radiator hoses, this can result in coolant loss and engine overheating. In V-belts, a torn belt can cause the alternator, power steering, or water pump to fail. Therefore, you should regularly inspect ribbed components for damage.

Benefits of Ribbing for Car Mechanics

The ribbing on components often facilitates assembly and disassembly. The increased grip allows for secure handling. Furthermore, ribbing provides clues for diagnosing damage. Deformations or cracks in the ribs can indicate problems in the system.

Related Questions About Ribbing

- What is the difference between a smooth and a ribbed radiator hose?

- How often should the V-belt be replaced?

- What are the signs of a faulty radiator hose?

More Information on AutoRepairAid.com

On our website, you will find more helpful articles on topics related to car repair, such as diagnosing engine damage or maintaining the braking system.

Need Help with Car Repair?

We at AutoRepairAid.com are here to assist you with our team of experts. Feel free to contact us via WhatsApp at + 1 (641) 206-8880 or by email at [email protected]. We’re here to help!

Conclusion

Ribbing is an important aspect in car repair, both in the constructive sense and in colloquial usage. As a car mechanic, you should understand the different meanings of the term and regularly inspect the corresponding components for damage. This way, you can ensure the optimal function of the vehicle and protect your customers from unnecessary costs.