Calculating panel gaps, often overlooked, is crucial for quality auto repair. Accurate gap measurement ensures structural integrity and proper part fit. This article covers everything about calculating panel gaps, from definition to practical tips.

What Does “Calculating Panel Gaps” Mean?

“Calculating panel gaps” means precisely determining the distance between two metal parts to be welded or bonded. This distance, the panel gap, significantly impacts the joint’s strength and durability. A gap that’s too large or too small can create weak points and compromise vehicle safety. Economically, an incorrectly calculated gap leads to rework and wasted materials. From an experienced mechanic’s perspective, accurate gap calculation demonstrates professionalism and care.

Panel Gap: Definition and Importance

The panel gap is the precise distance between the edges of two metal panels being joined. This distance is critical for successful repair. A correctly calculated gap ensures enough material for a stable weld or bond without damaging or deforming surrounding areas. Accurate panel gap calculation is central to body repair, significantly contributing to restoring the vehicle’s original structure. As Dr. Karl Schmidt, author of “Modern Body Repair,” emphasizes: “Precision in panel gap is key to a successful repair.”

How to Calculate Panel Gaps

Calculating panel gaps requires precise measurements and considering factors like material thickness, joint type, and manufacturer specifications. Specialized tools like digital calipers, depth gauges, and specific templates are used. Manufacturer repair manuals often provide panel gap specifications.

Technician measuring a panel gap during auto repair

Technician measuring a panel gap during auto repair

Benefits of Accurate Panel Gap Calculation

Accurate panel gap calculation offers numerous benefits for auto technicians:

- Optimal Weld Quality: A correct gap allows for a uniform and stable weld.

- Avoidance of Distortion: A gap that’s too small can lead to material warping and stress in the metal.

- Improved Corrosion Resistance: An optimal gap minimizes corrosion risk in the weld.

- Time Savings: Precise gap calculation avoids rework, saving valuable time.

Frequently Asked Questions about Panel Gap Calculation

- Which measuring tools do I need? Digital calipers, depth gauges, and specific templates are essential.

- Where can I find the manufacturer’s specifications? In the repair manuals of the respective vehicle manufacturer.

- What happens if the panel gap is incorrect? It can lead to weak points, distortion, and corrosion.

More Questions About Auto Body Repair:

- How to effectively remove rust from a car?

- Which welding methods are suitable for auto body repair?

- How to paint a car professionally?

Visit autorepairaid.com for more information and helpful tips on auto repair. We also offer a wide selection of diagnostic tools and technical literature.

Calculating Panel Gaps: Precision for Safety and Quality

Precise panel gap calculation is fundamental to professional auto body repair. It ensures the repair’s stability, safety, and longevity. Rely on accurate measurements and manufacturer specifications for optimal results.

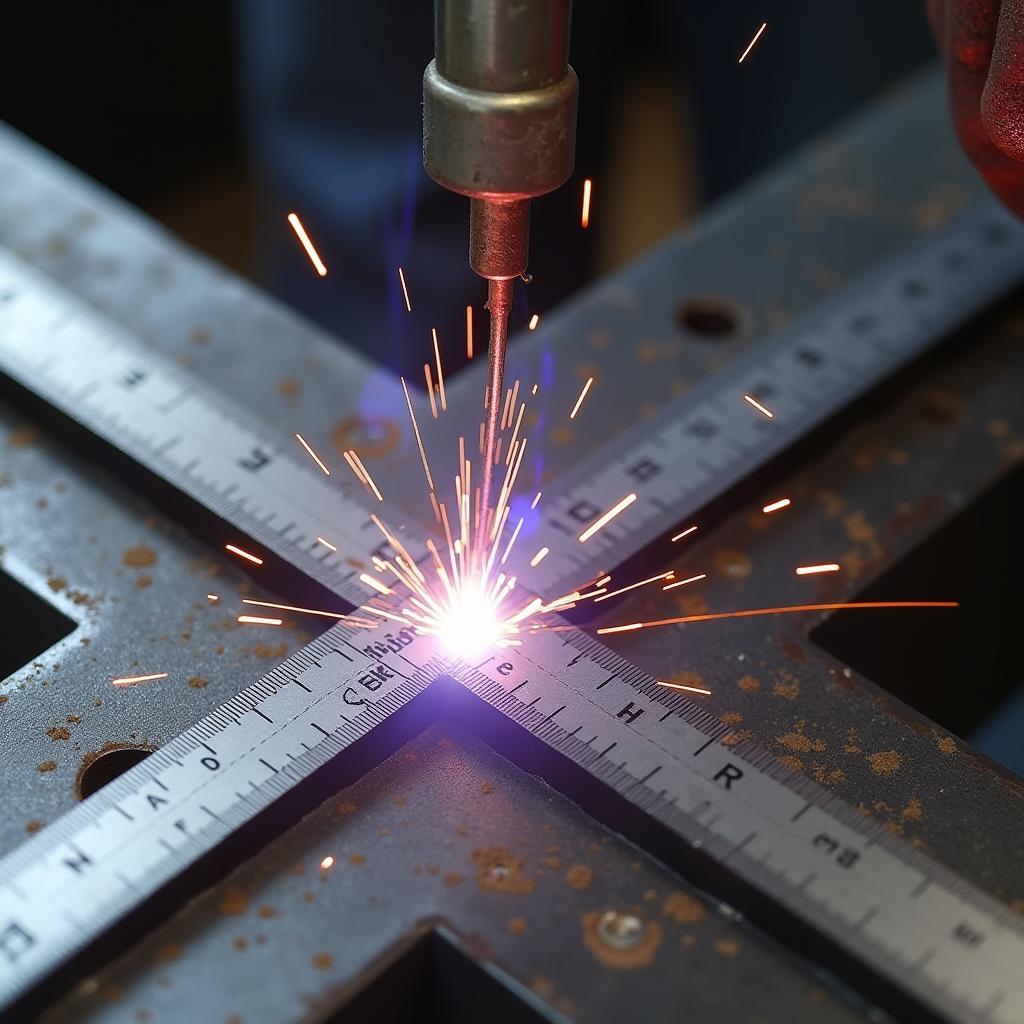

A perfectly calculated panel gap and the finished result

A perfectly calculated panel gap and the finished result

Need help repairing your vehicle? Contact us through our website autorepairaid.com. Our automotive experts are available 24/7.