The punch cut is a term that frequently appears in the world of auto repair. But what exactly is it? This article explores the punch cut from various angles, from its technical definition to practical applications and the benefits for auto technicians.

What is a Punch Cut?

A punch cut, also known as a “popper cut” or “die cut,” is a specialized technique for separating sheet metal or other materials in auto body construction. It utilizes a specific tool, often called a “popper” or “punch tool,” which uses pneumatic or hydraulic force to create a clean and precise hole or cut. This method is commonly used in repairing accident damage, replacing body panels, or modifying vehicles.

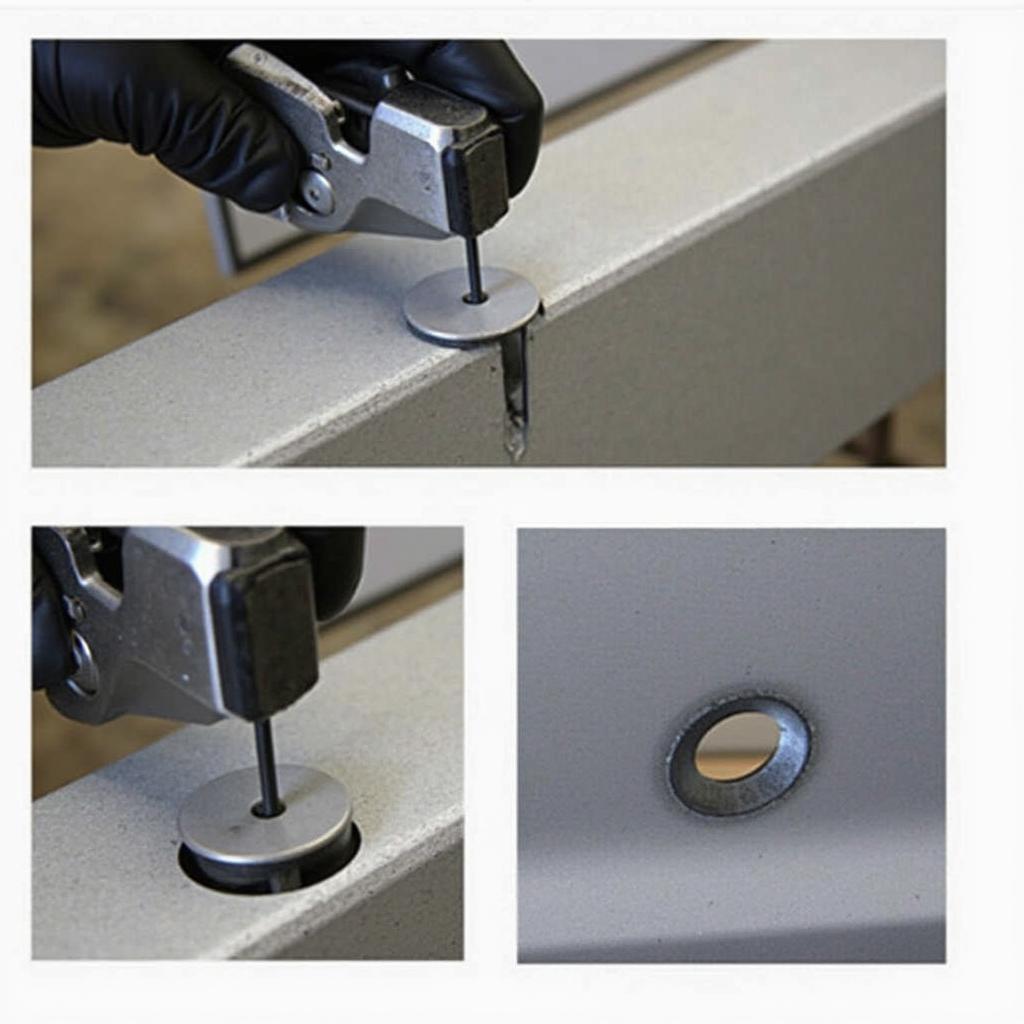

Punch cut in action for auto body repair

Punch cut in action for auto body repair

Advantages of the Punch Cut in Auto Repair

The precision of the punch cut minimizes the risk of deformation or damage to the surrounding material. This is particularly important when working on delicate body parts. Furthermore, the punch cut enables fast and efficient work, saving both time and costs. “A clean punch cut is the foundation for successful auto body repair,” states renowned auto expert Dr. Karl Heinz Müller in his book “Modern Auto Body Technology.”

Applications of the Punch Cut

The punch cut is applied in various areas of auto repair. For example, it can be used to cut out damaged sheet metal parts to create space for a new replacement part. The punch cut is also used when installing sunroofs or modifying vehicle bodies.

Punch Cut vs. Other Cutting Techniques

Compared to conventional cutting methods like using a grinder (flexing), the punch cut offers several advantages. It generates less heat and sparks, reducing the risk of fire damage. Additionally, the cut is more precise and cleaner, minimizing rework.

Safety Tips for Punch Cut

When working with a punch tool, it is crucial to take appropriate safety precautions. This includes wearing safety glasses and gloves and ensuring adequate ventilation in the work area. “Safety first – even with punch cuts,” emphasizes safety expert John Smith in his work “Safe Practices in Auto Repair.”

Punch Cut: Frequently Asked Questions

- What materials can be cut with the punch tool? Primarily sheet metal, but other materials such as aluminum or plastics can also be processed.

- What types of punch tools are there? There are different types of punch tools that vary in size, shape, and drive type.

- Is special training required to use the punch tool? Instruction in the safe handling of the tool is recommended.

Further Information and Support

Do you need more information about punch cuts or have other questions about auto repair? Visit our website autorepairaid.com for more articles and resources. We also offer a wide range of diagnostic equipment and training materials for auto technicians. Feel free to contact us for individual advice!

Conclusion: Precision and Efficiency in Auto Repair

The punch cut is a valuable technique in modern auto repair. Its precision, efficiency, and versatility make it an indispensable tool for professional auto technicians.

For further assistance and advice, our experts are at your disposal. Contact us via WhatsApp at +1 (641) 206-8880 or by email at [email protected].