Plexiglas rods are a fascinating material finding applications in car repair due to their versatility and robustness. In this article, you will learn more about the properties, applications, and benefits of Plexiglas rods in the context of the auto repair shop.

What is a Plexiglas Rod and What is it Used For?

A Plexiglas rod, also known as an acrylic rod, is an extruded or cast rod made of polymethyl methacrylate (PMMA). This material is characterized by high transparency, impact resistance, and weather resistance. In car repair, the Plexiglas rod can be used for various purposes, such as a template, spacer, or for creating prototypes and models. Sometimes it is also used in the repair of headlight lenses or other plastic parts.

Dr. Karlheinz Schmidt, author of “Innovative Materials in Automotive Engineering,” emphasizes the importance of Plexiglas in modern vehicle construction: “The combination of lightness, strength, and formability makes acrylic glass a valuable material that constantly finds new areas of application.”

Benefits of Plexiglas Rods in the Auto Repair Shop

Plexiglas rods offer several advantages over other materials: they are easy to work with, can be sawed, drilled, and glued. Furthermore, they are resistant to many chemicals and UV radiation. The transparency of the material allows for good visibility and facilitates precise work. Compared to glass, Plexiglas is significantly more shatterproof and lighter, which simplifies handling.

Cost-Effectiveness and Easy Handling

Another advantage of Plexiglas rods is their cost-effectiveness. They are available in various sizes and diameters at affordable prices. Their easy handling and workability save time and costs in the workshop.

Working with Plexiglas rods in an auto repair shop

Working with Plexiglas rods in an auto repair shop

Application Examples for Plexiglas Rods

The potential uses of Plexiglas rods in the auto repair shop are diverse:

- Templates: For precise creation of cutouts or drillings.

- Spacers: For fixing components during repair.

- Model Making: For creating prototypes or visualizing repair processes.

- Light Guides: For special lighting applications in the interior or on the exterior of the vehicle.

“Using Plexiglas rods as aids in repair can significantly increase the efficiency and precision of the work,” states engineer Amelia Russo in her book “Practical Guide to Car Repair.”

Plexiglas Rod vs. Other Materials

Compared to other materials like metal or wood, Plexiglas rods offer several advantages, particularly regarding weight, transparency, and workability. While metal rods are heavy and often prone to corrosion, Plexiglas is lightweight and weather-resistant. Wood rods can splinter or absorb moisture, while Plexiglas rods are dimensionally stable and moisture-resistant.

What to Look for When Buying Plexiglas Rods

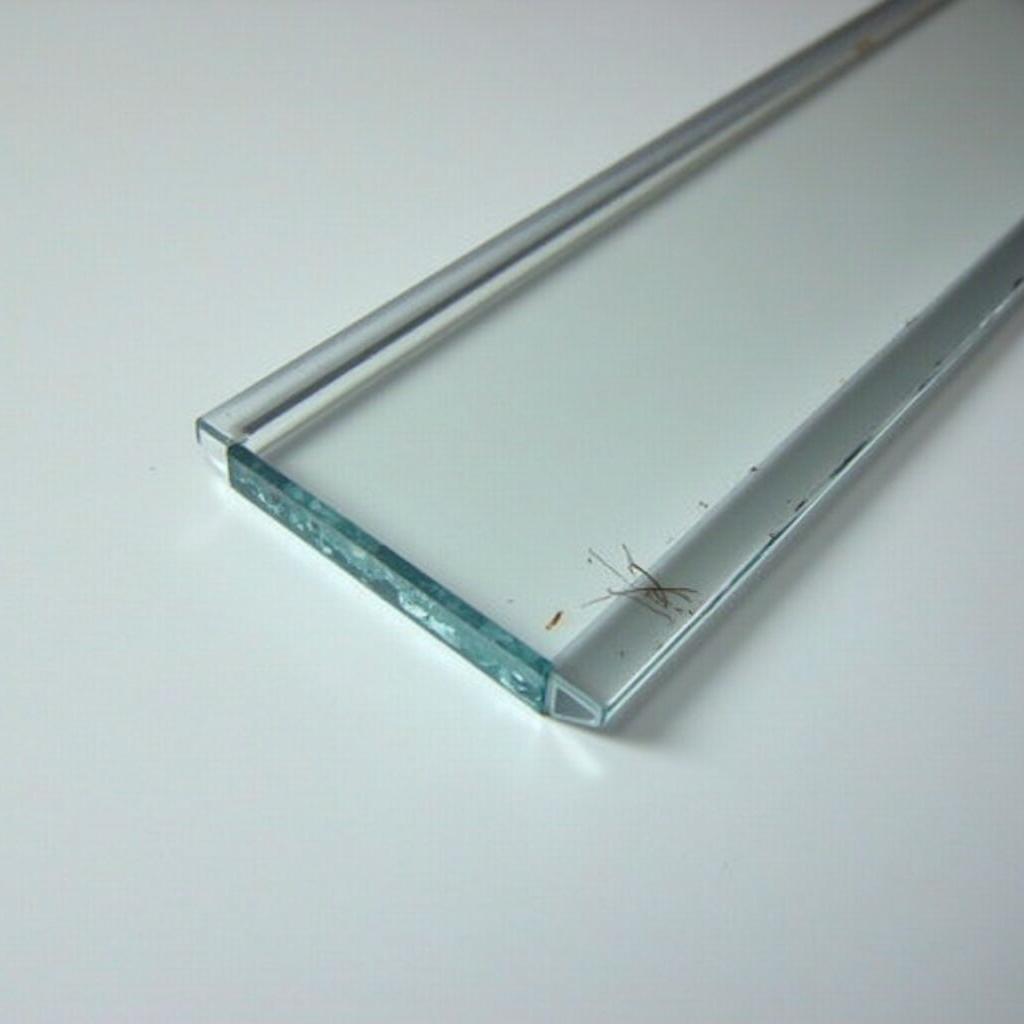

When buying Plexiglas rods, pay attention to the quality of the material. High-quality Plexiglas is free of bubbles and scratches and exhibits uniform transparency. Also, make sure to choose the correct diameter and required length of the rod.

Quality checking Plexiglas rods

Quality checking Plexiglas rods

Need Assistance with Car Repair?

Our experts at autorepairaid.com are available to you around the clock. Contact us for professional advice and support with all your car repair questions. We offer not only comprehensive services but also state-of-the-art diagnostic tools and helpful self-study guides.

Plexiglas Rods: A Conclusion

Plexiglas rods are a versatile and useful material in car repair. They offer numerous advantages and allow for precise and efficient work. From template creation to model making – Plexiglas rods are a valuable aid for any automotive technician.

Do you have questions about Plexiglas rods or other topics related to car repair? Leave us a comment or share this article! Also, check out our other articles on autorepairaid.com for more helpful tips and information.