Hydraulics are central to modern trucks, enabling power transmission for a wide range of functions. From steering and braking to tilting the loading platform and operating cranes – truck hydraulics are ubiquitous. However, like any complex technology, they are also susceptible to wear and failures.

Imagine you’re in the middle of an important delivery when suddenly your truck’s hydraulics fail. The steering becomes stiff, the brakes react slowly – a potentially dangerous situation!

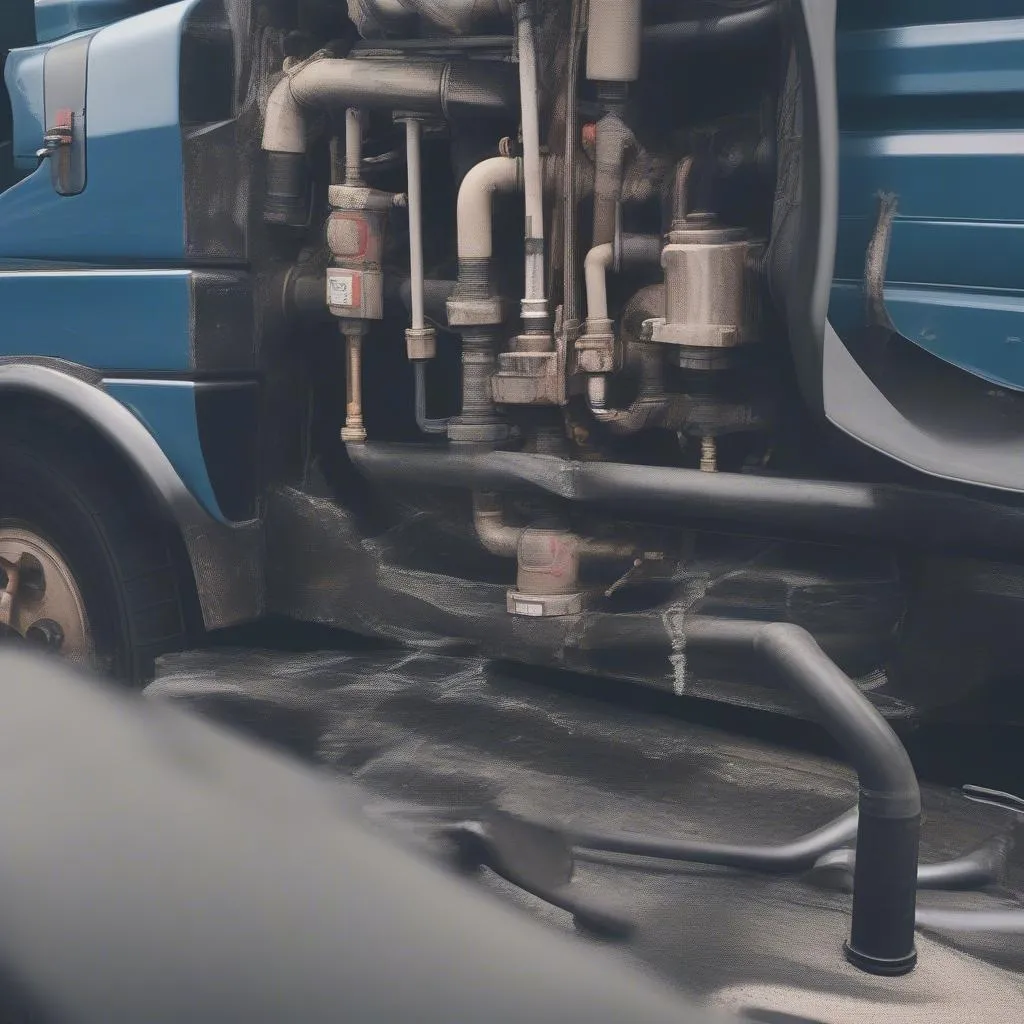

Truck hydraulic system failure

Truck hydraulic system failure

Common Truck Hydraulic System Problems

Here are some of the most common problems that can occur in truck hydraulic systems:

- Leaks: Hydraulic oil is the lifeblood of the system. Leaks, whether in hoses, seals, or cylinders, can lead to loss of performance and eventually to failure.

- Air in the System: If air enters the hydraulic system, it can lead to a “spongy” feeling when braking or steering.

- Worn Pumps: The hydraulic pump is the heart of the system. Pump failure can lead to a total hydraulic failure.

- Faulty Valves: Valves control the flow of hydraulic oil. Defective valves can lead to malfunctions and loss of performance.

Troubleshooting and Repair

Diagnosing problems with truck hydraulics requires experience and expertise. An experienced mechanic can:

- Perform visual inspections to detect leaks or damage to hoses, lines, and components.

- Check the oil pressure to ensure proper functioning of the pump and valves.

- Check the oil level and oil quality to detect contamination or impurities.

- Use diagnostic tools to read out error codes and analyze system performance.

Mechanic repairing truck hydraulics

Mechanic repairing truck hydraulics

Truck Hydraulic System Maintenance

Regular maintenance is crucial to maximize the lifespan and reliability of your truck hydraulics. This includes:

- Regular oil changes: Contaminated or worn hydraulic oil can lead to premature wear of components.

- Inspection of hoses and lines: Check for cracks, abrasions, or leaks.

- Filter checks: Dirty filters can restrict oil flow and impair performance.

Benefits of Well-Maintained Truck Hydraulics

Well-maintained truck hydraulics offer numerous benefits, including:

- Improved Safety: A reliable hydraulic system is crucial for safe braking, steering, and maneuvering of the truck.

- Reduced Downtime: Regular maintenance prevents costly breakdowns and downtime.

- Extended Component Life: Proper maintenance and care extend the lifespan of hydraulic system components.

- Optimal Performance: A well-maintained hydraulic system operates more efficiently and delivers maximum performance.

“A well-maintained hydraulic system is like a well-oiled machine,” says Hans Schmidt, an experienced truck mechanic from Berlin. “It runs smoother, lasts longer, and saves you a lot of trouble in the long run.”

Frequently Asked Questions about Truck Hydraulics

What are signs of truck hydraulic problems?

Signs of truck hydraulic problems include a “spongy” feeling when braking or steering, unusual noises from the hydraulic system, loss of power, slow hydraulic response, and visible leaks.

How often should truck hydraulics be serviced?

The service frequency depends on usage and manufacturer recommendations. However, it is generally recommended to have truck hydraulics serviced at least once a year or every 2,000 operating hours.

How much does truck hydraulic repair cost?

Repair costs depend on the nature of the problem and the replacement parts needed. It is advisable to obtain multiple quotes from qualified workshops.

Truck hydraulic system components

Truck hydraulic system components

Conclusion

Truck hydraulics are a complex system that is essential for the safe and efficient operation of your truck. Through regular maintenance and timely repairs, you can ensure that your hydraulic system remains in perfect condition and gets you to your destination safely and reliably. If you have any questions or problems with your truck hydraulics, contact a qualified mechanic.

Need Help with Your Truck Hydraulics?

We at autorepairaid.com are your experts for truck repairs of all kinds. Contact us today to make an appointment!