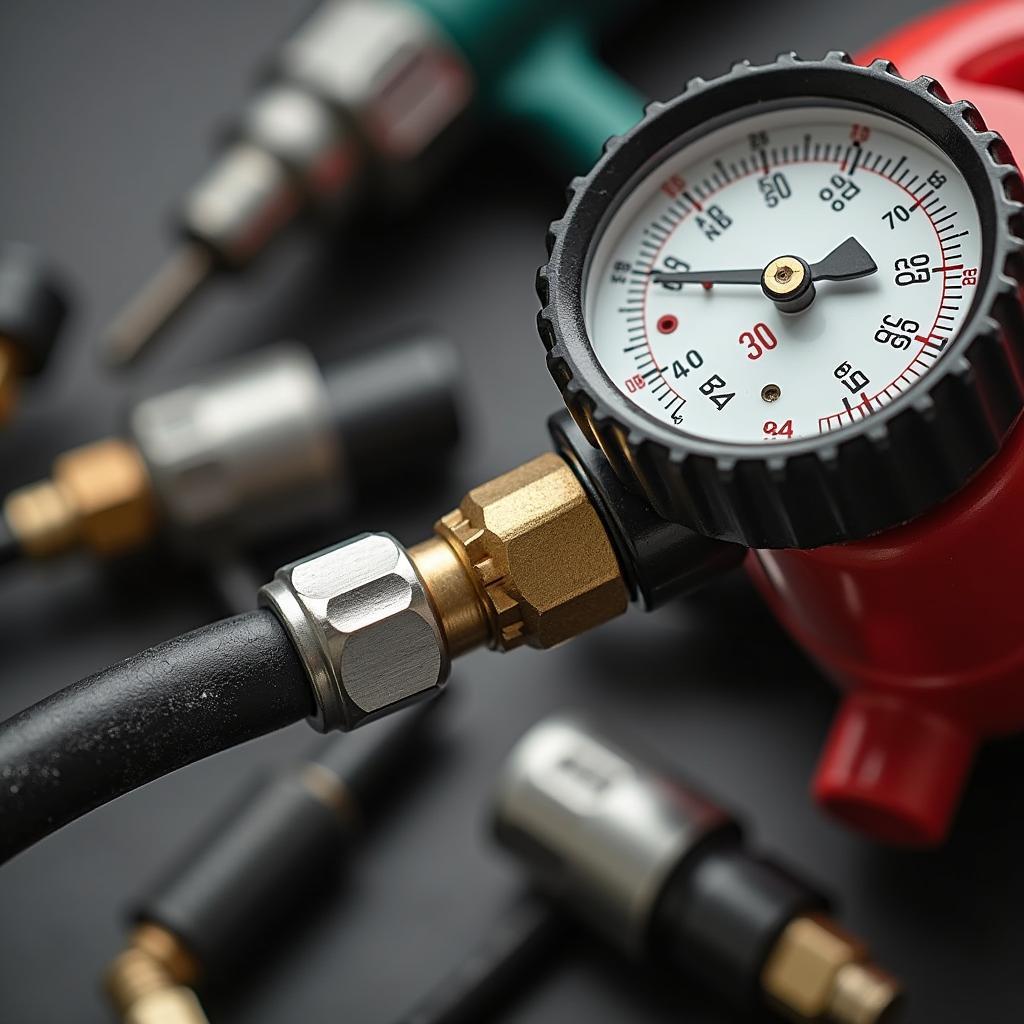

Choosing the right air hose can be a challenge for many car owners. The question of the optimal diameter, in particular, often raises questions. However, the correct diameter is crucial to ensure the full performance of your pneumatic tools and to avoid costly compressed air losses.

What Does Air Hose Diameter Mean?

The diameter of an air hose refers to the internal diameter of the hose and is specified in millimeters. It determines how much air can flow through the hose simultaneously. A larger diameter means a higher airflow, which is essential for high-performance pneumatic tools.

Imagine the hose as a highway: a larger diameter is equivalent to more lanes, allowing more cars to pass at the same time.

Understanding Air Hose Diameter

Understanding Air Hose Diameter

Air Hose Diameter: How to Find the Right Size

Choosing the right hose diameter depends on various factors, including:

- Tool’s Air Requirement: Each pneumatic tool has a specific air requirement, specified in liters per minute (l/min) or cubic feet per minute (cfm). This value should be found in the tool’s operating manual.

- Hose Length: The longer the hose, the larger the diameter should be to minimize pressure loss.

- Operating Pressure: Higher operating pressure requires a larger hose diameter to withstand the pressure.

As a rule of thumb:

- For small pneumatic tools like tire inflators or blowguns, a hose with a diameter of 6 mm is usually sufficient.

- For medium-sized tools like impact wrenches or pneumatic nailers, a hose diameter of 8-10 mm is recommended.

- For large, high-performance tools like sandblasters or paint spray guns, a hose with a diameter of 12 mm or more should be used.

“A hose diameter that is too small can lead to a drop in tool performance,” explains Dr. Ing. Hans Schmidt, an expert in compressed air technology at the Technical University of Munich. “This can shorten the tool’s lifespan and impair work efficiency.”

Benefits of the Correct Hose Diameter

Choosing the correct hose diameter offers a range of benefits:

- Optimal Tool Performance: Sufficient airflow ensures the full performance of your pneumatic tools.

- Reduced Pressure Loss: A larger diameter minimizes pressure loss, especially with longer hoses.

- Extended Tool Lifespan: A constant airflow protects the mechanics of your tools, thus extending their lifespan.

- Energy Saving: By avoiding compressed air losses, you save energy and therefore costs.

Achieving optimal tool performance with the correct air hose

Achieving optimal tool performance with the correct air hose

Common Questions About Air Hose Diameter

- Can I use a larger hose diameter than my tool requires?

Yes, a larger hose diameter is usually not a problem. It ensures that sufficient air reaches the tool, even with longer hoses and higher air requirements. - What material is best suited for an air hose?

Air hoses are available in various materials, e.g., PVC, rubber, or polyurethane. Each material has its own advantages and disadvantages. PVC hoses are inexpensive and flexible, while rubber hoses are more robust and resistant to mechanical stress. Polyurethane hoses are particularly lightweight and flexible. - How should I store an air hose correctly?

Always store air hoses dry and protected from direct sunlight. Avoid kinking or crushing the hose, as this can affect the hose’s lifespan.

Related Topics: Compressed Air

- Air Compressors: Selection and Application

- Pneumatic Tools: Maintenance and Care

- Safety Instructions for Handling Compressed Air

Visit our website autorepairaid.com for more information and helpful tips on car repair. Do you need support in choosing the right air hose? Our experts are happy to assist you!