A torque wrench is an indispensable tool in any workshop, especially when it comes to correctly fastening bolts. However, like any precision tool, a torque wrench requires regular checking and, if necessary, calibration to ensure its accuracy. Find out why this is so important and how you can perform the check yourself in this article.

Why Is Checking Your Torque Wrench So Important?

Imagine this: You’re changing the brake discs on your vehicle and tightening the bolts with your torque wrench. What you don’t know is that your torque wrench is misaligned and isn’t delivering the set torque. The consequences can be fatal: from loose bolts that come undone while driving to overtightened threads that can lead to material failure in the worst case.

“A correctly adjusted torque wrench is essential for the safety and longevity of components,” says Dr. Ing. Hans Müller, Mechanical Engineer and Expert in Bolt Connections. “Even minor deviations from the specified torque can lead to serious damage.”

How to Check Your Torque Wrench

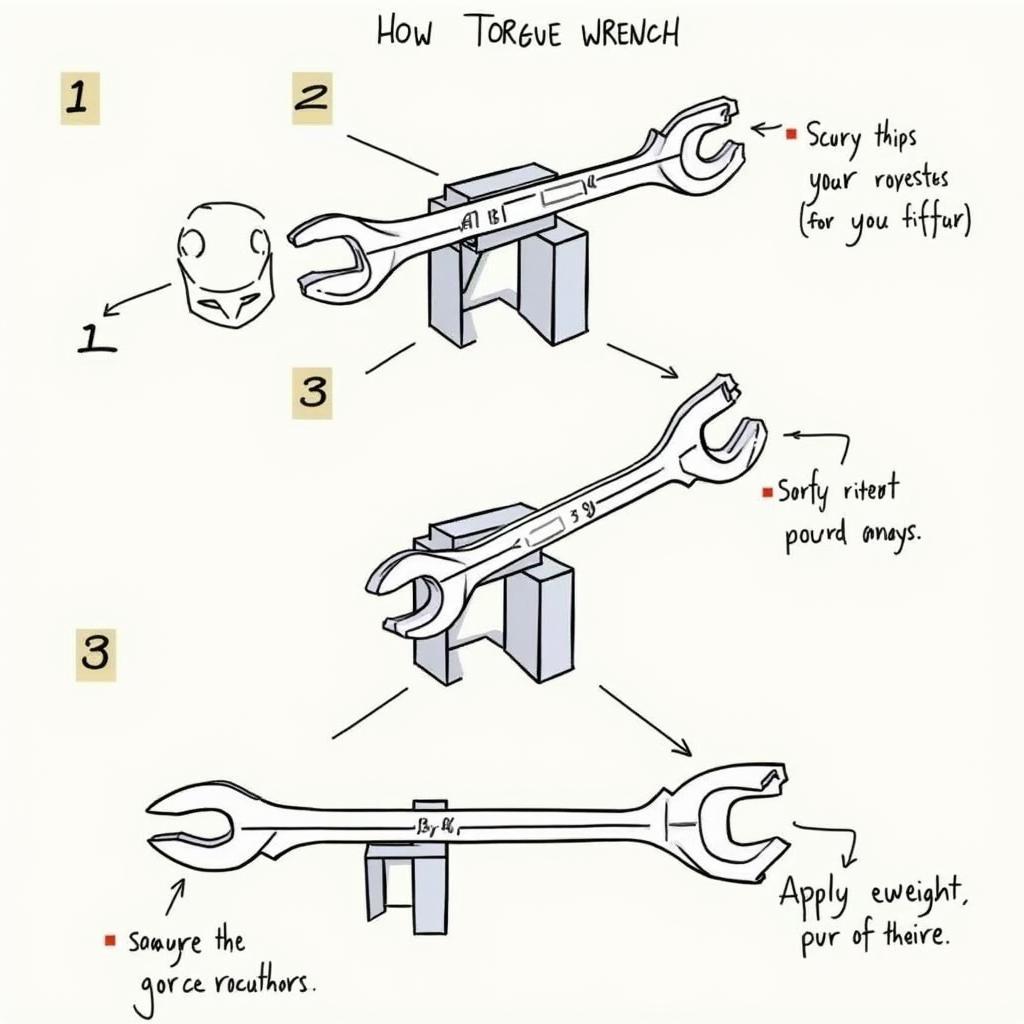

You can check your torque wrench yourself with simple tools. You only need a vice, a high-precision scale, and a little patience. Here’s how to proceed:

- Preparation: Clamp the torque wrench horizontally in the vice so that the head can move freely. Attach the scale to the wrench handle, as close as possible to the pivot point.

- Measurement: Set a torque value on the wrench, e.g., 50 Nm. Now slowly and evenly hang a weight on the scale until the wrench clicks. Note the weight at which the wrench triggers.

- Calculation: Multiply the weight (in kg) by the lever arm length (in meters) – the distance from the pivot point to where the scale is attached. The result is the actual torque your wrench delivers.

- Evaluation: Compare the measured torque with the set torque. If the deviation is within the manufacturer’s tolerance limits, your wrench is okay.

Setup for checking a torque wrench using a vice and scale

Setup for checking a torque wrench using a vice and scale

Tip: You can usually find the tolerance limits in your torque wrench’s user manual.

What to Do with Deviations?

If your torque wrench shows deviations, you should get it calibrated. This can be done at specialist workshops or directly by the manufacturer. Regular calibration, ideally once a year, is especially recommended if you use the wrench frequently or if it is subjected to heavy loads.

Further Tips for Handling Torque Wrenches

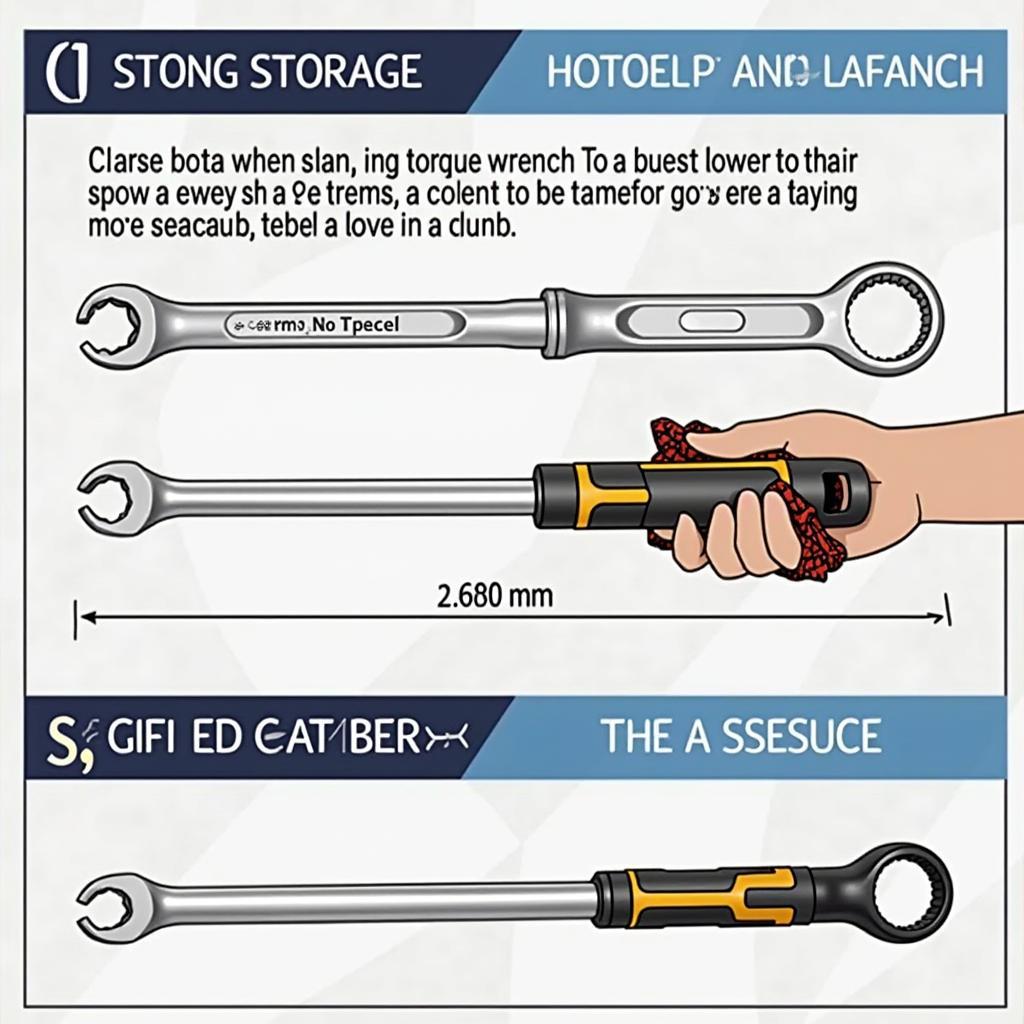

- Always store your torque wrench in an unloaded state, i.e., with the lowest torque setting.

- Avoid shocks and impacts to the wrench.

- Regularly clean the wrench of dirt and oil.

Proper storage and cleaning methods for a torque wrench

Proper storage and cleaning methods for a torque wrench

By following these tips, you can ensure that your torque wrench serves you reliably for a long time and that your bolted connections are always tightened with the correct torque.

Want to learn more about maintaining and repairing your vehicle? Visit our website autorepairaid.com for more helpful articles and guides, such as:

If you have questions about car repair, our experts are happy to assist you. Contact us through our website – we’re here to help!