When dealing with heavy loads in an auto repair shop, reliability and safety are paramount. This is where heavy-duty anchors come into play, ensuring a rock-solid fastening – and when it comes to quality and innovation, Hilti is at the forefront. But what exactly makes Hilti heavy-duty anchors the first choice for auto repair professionals, and how are they used correctly? This guide provides you with all the important information.

What are Heavy-Duty Anchors and Why are They So Important?

Imagine having to attach an engine hoist or a lift to your workshop floor. Conventional fastening methods quickly reach their limits here. Heavy-duty anchors offer the solution: These robust fasteners are anchored in concrete or masonry and can withstand even enormous tensile and shear forces.

“The use of heavy-duty anchors is essential when it comes to safety in the workshop,” explains Dr. Markus Schmidt, a renowned expert in fastening technology. “Especially with lifting devices or other heavy equipment that pose a risk in the event of failure, high-quality heavy-duty anchors are indispensable.”

Hilti heavy-duty anchor in use

Hilti heavy-duty anchor in use

Hilti Heavy-Duty Anchors: Quality You Can Rely On

Hilti has been synonymous with quality and innovation in fastening technology for decades. The company’s heavy-duty anchors are characterized by the following features:

- Highest load capacity: Hilti heavy-duty anchors are made of high-quality materials and subjected to strict quality controls.

- Easy installation: Thanks to sophisticated systems and special tools, Hilti heavy-duty anchors can be installed quickly and easily.

- Versatile applications: Whether concrete, masonry, or other substrates – Hilti offers the right heavy-duty anchor for every requirement.

“We at AutoRepairAid.com have relied on Hilti heavy-duty anchors for years,” says Michael Wagner, lead mechanic at AutoRepairAid.com. “The quality of the products is unsurpassed and gives us the confidence that our workshop is optimally equipped.”

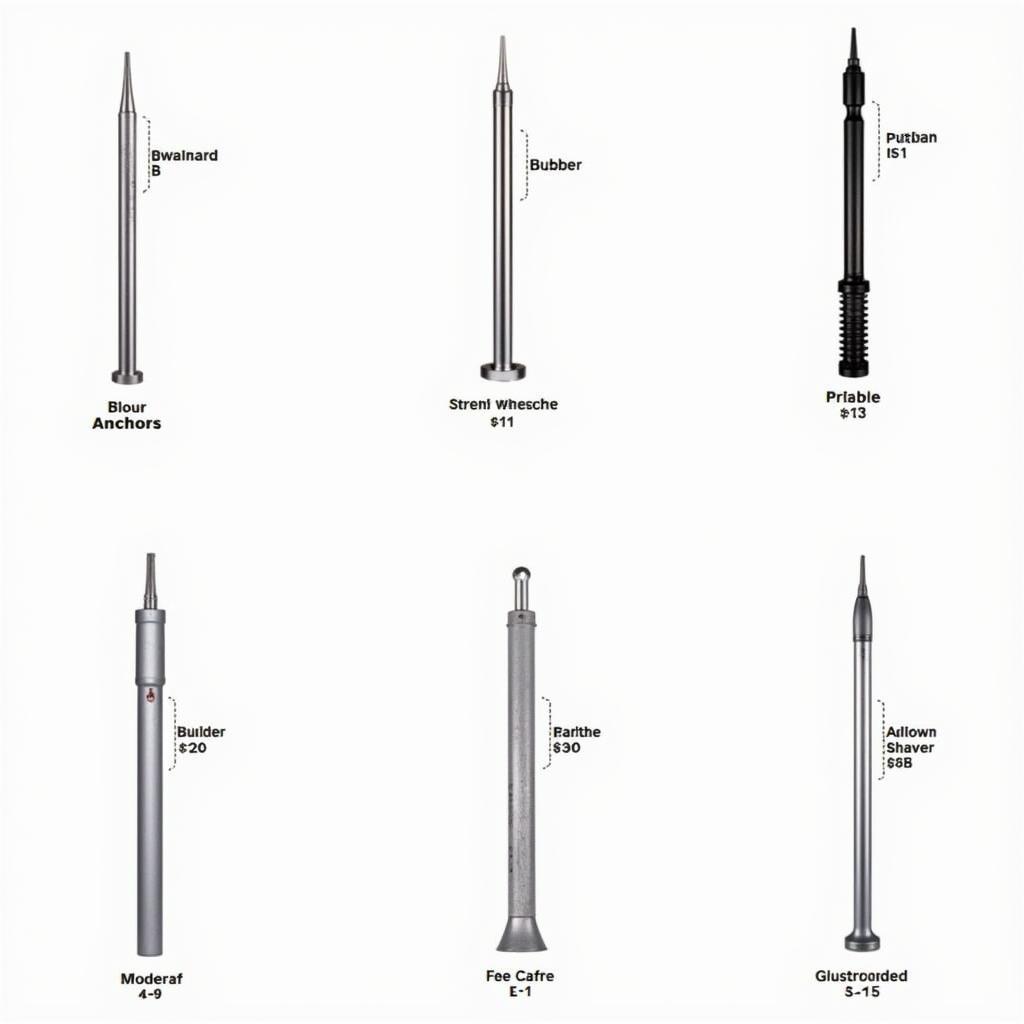

Choosing the Right Heavy-Duty Anchor

The choice of the right heavy-duty anchor depends on various factors, such as:

- Load requirements: How high are the expected tensile and shear forces?

- Substrate: What material is the substrate made of (concrete, masonry, etc.)?

- Installation conditions: Is there sufficient space available for installation?

Hilti offers a wide range of heavy-duty anchors for different requirements. To find the optimal solution for your workshop, we recommend that you contact our experts.

Different types of Hilti heavy-duty anchors

Different types of Hilti heavy-duty anchors

Tips for the Safe Use of Heavy-Duty Anchors

- Planning is key: Before installation, determine the exact position of the heavy-duty anchors and mark them carefully.

- Correct tools: Use only tools suitable for Hilti heavy-duty anchors to ensure safe and professional installation.

- Cleaning the drill hole: After drilling the anchor hole, carefully remove drilling dust and other residues to ensure optimal adhesion of the anchor.

- Checking the fastening: After installation, check the strength of the heavy-duty anchors by subjecting them to a test load.

Conclusion

Heavy-duty anchors are indispensable helpers in every auto repair shop. With Hilti heavy-duty anchors, you are relying on quality and safety that is second to none. If you have any questions about the selection or application of heavy-duty anchors, our experts at AutoRepairAid.com are always available to assist you. Contact us today – we look forward to helping you!

More Interesting Topics Related to Your Workshop:

- Torque Wrenches: Precision for Your Bolted Connections

- Diagnostic Devices: Finding Errors Quickly and Easily

- Workshop Equipment: How to Optimize Your Workplace

Visit AutoRepairAid.com for more helpful information, tips, and tricks related to auto repair!